Steel structure refers to a type of construction where steel plates, profiles, and other types of steel are used as the main components, connected through welding, fasteners, and other methods. It has advantages such as recyclability, environmental friendliness, and ease of industrial production. Steel structures are typical of green, energy-saving structures that meet the requirements of the circular economy and sustainable development.

1.Large Scale Steel Structure Robot Intelligent Welding Technology Solution

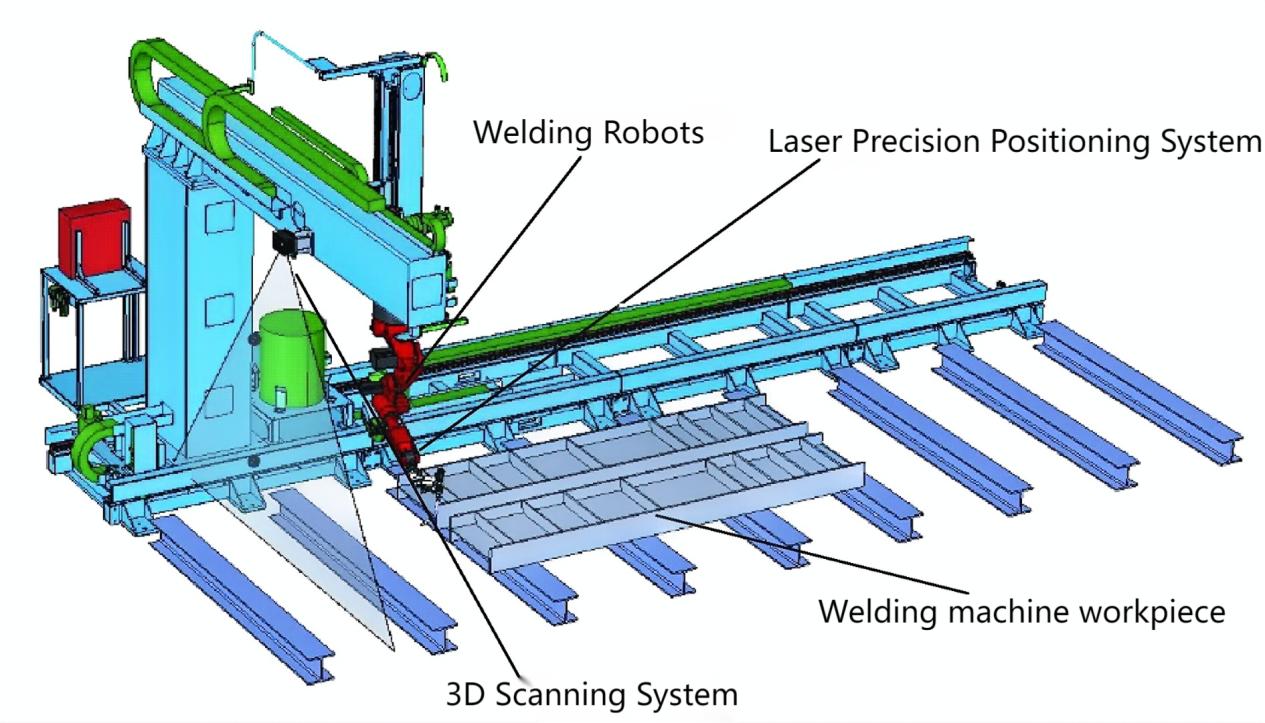

For the characteristics of building steel structures, a solution is proposed that uses panoramic visual scanning and laser positioning technology in combination as a hybrid sensing method. This solution enables fast and accurate measurement of weld seam positions, eliminating the need for pre-welding programming and teaching. The overall design of the solution is shown in the diagram. By matching the workpiece profile with the weld seam dimension model, and integrating intelligent features such as automatic motion path planning, automatic welding sequence sorting, automatic weld bead arrangement, and automatic process specification calling, the system can quickly achieve intelligent welding without teaching for different structures such as H-shaped, box-shaped, and stiffened plates.

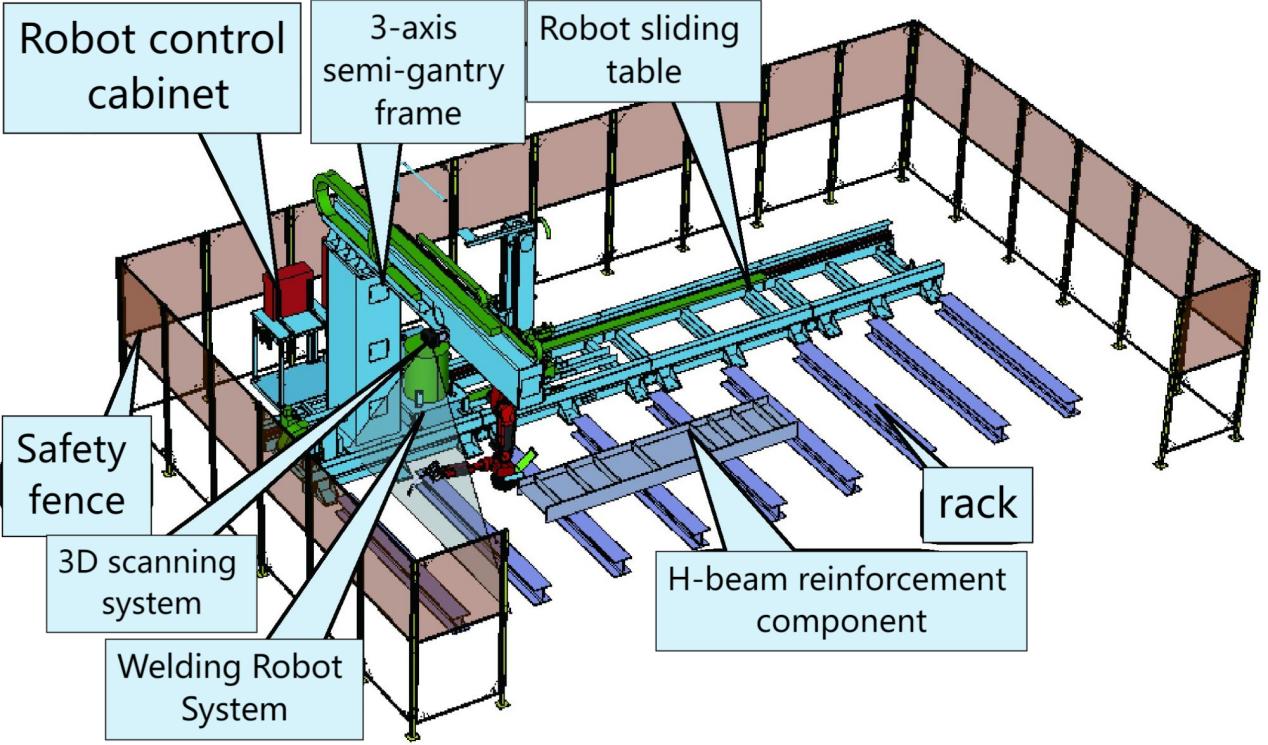

2.Large-Scale Steel Structure Robotic System Integration

The robotic equipment uses a cantilever structure, with a manipulator mounted upside down under the beam of a movable gantry. The gantry moves along a longitudinal track, and the manipulator can move horizontally along the beam. The working range of the manipulator covers the entire welding unit. A laser sensor mounted on the gantry beam scans and collects the workpiece profile to automatically identify the weld positions. Adaptive Logic Programming Technology (ALPT) is used to intelligently plan the welding path based on the collected data. The workstation hardware includes: one set of sliding tables, one set of 3-axis semi-gantry, one set of robotic system, one set of welding system, one set of 3D scanning system, safety fences, etc. The diagram below shows the robotic hardware system.

3.Large-Scale Steel Structure Intelligent Welding Process

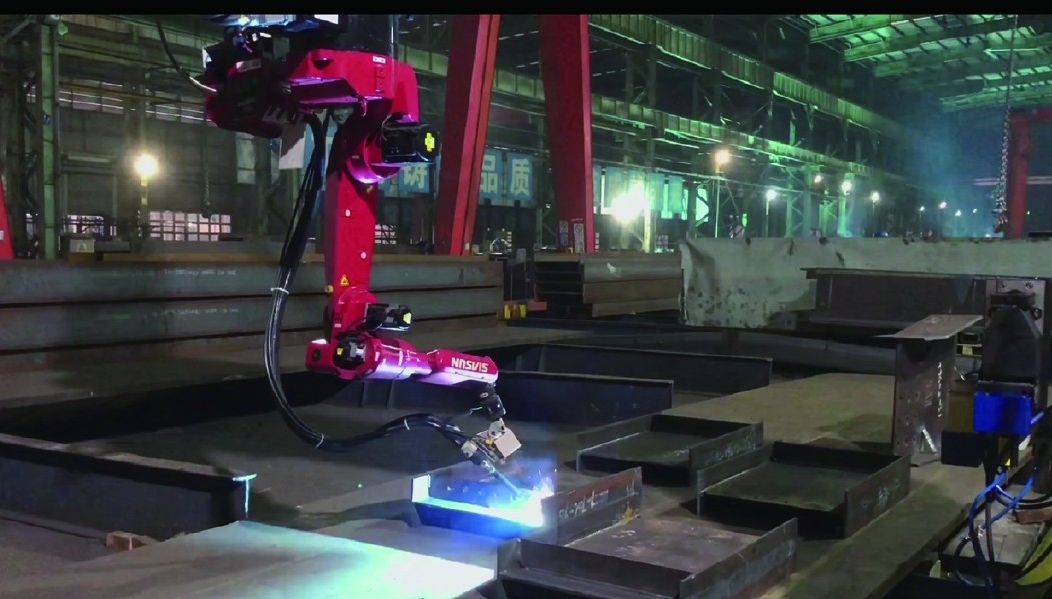

The robot integrates with a 3D camera. By scanning the steel structure, the robot automatically identifies the weld seam profile and transmits the data to the intelligent management and analysis system. This system collects and stores the visual data, matches the workpiece type, and then the upper-level platform system parses the visual data to automatically generate the welding program. The intelligent management system then sends the program to the welding robot to carry out the welding operation. The robotic welding process is shown in the diagram below.