cnc large pipe cutting machine

adopt Rolling bed , poduced by gantry milling machine one time processing .Large Pipe Plasma Cutting Machine is a specialized machine for cutting and processing large diameter pipes and cylinders. It is an efficient and precise cutting tool, which is usually used in various industrial fields, such as petrochemical industry, shipbuilding, bridge construction, transmission pipeline and so on.

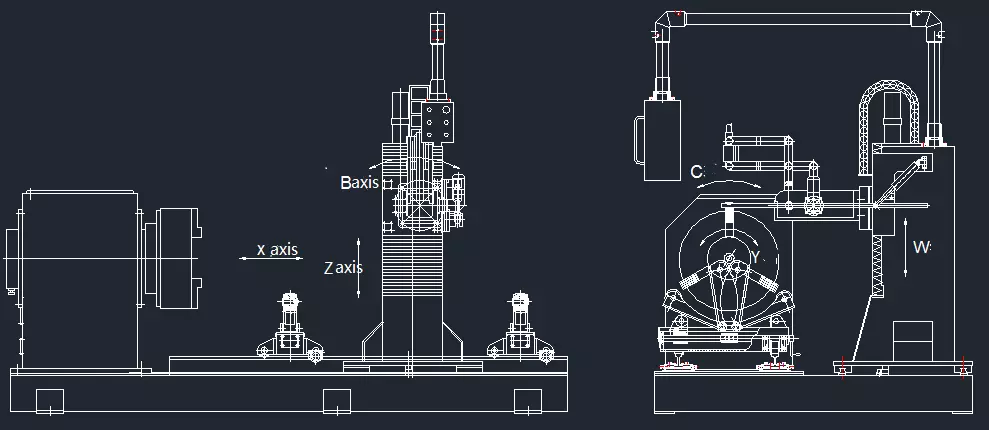

6 axis moving show

| No. | Items | Parameters |

| 1 | Cutting diameter | Φ= 600 mm to 1200 mm |

| 2 | Plasma bevel thickness | 40mm |

| 3 | Plasma source | LGK, Hypertherm,Kjellberg |

| 4 | Plasma cutting thickness of pipe wall | 40mm (according to Plasma source) |

| 5 | Valid cutting length | 12000mm |

| 6 | Requirements of angle | ≤1% |

| 7 | Cutting speed | 10~2000mm/min |

| 8 | Moving speed | 10~6000 mm/min |

| 9 | Cutting torch wave angle of axis | α=±45° |

| 10 | Cutting torch wave angle of diameter | β=±45° |

| 11 | Can be cutting pipe max. Weight | 61000Kg |

Large Diameter Pipe Cutting: the machine is suitable for cutting large diameter pipes and cylinders, and is able to handle pipes of different sizes and thicknesses.

High efficiency: With fast cutting speed, the large pipe plasma cutting machine is able to complete the cutting task of large pipes efficiently and improve productivity.

Accuracy: Adopting advanced plasma cutting technology ensures the precision and accuracy of cutting and ensures that the cut pipe meets the specifications.

Multi-functionality: The large pipe plasma cutting machine can cut various metal materials, such as carbon steel, stainless steel, aluminum, etc. It is also suitable for non-metallic materials.

Flexibility: The machine has multi-axis control and automation functions, which can realize complex cutting shapes and angles to meet different application requirements.

Environmental protection: The plasma cutting process does not produce harmful waste gas and waste water, which meets the requirements of environmental protection.

Wide range of application: large pipe plasma cutting machine can be widely used in petrochemical industry, shipbuilding, bridge construction, transmission pipeline and other fields.

Big pipe cutting and bevelling machine